Boca Bearings Workshop

RC Boat Project: Update 2

The PLA hull was sanded down starting with a heavier P150 grit sandpaper. After that I switched to P220 and finally P320 to get the hull as smooth as possible. After I started sanding I soon realized that PLA is much less forgiving then I realized. It took approximately 3 hours to sand the PLA to a desirable smooth surface as see in figure 1.

Boca Bearings Workshop Weekly Update 15

Not much was done on my personal project this week because the group go kart took priority. However, the first half of the hull was printed and glued together with hub. More components were ordered so the pressure vessel and rods can start being assembled and machined. I printed the hull in safety orange, so you can see it clearly in the water.

Power Wheels Racer 2.0: Update 2

This week in the workshop we focused on the electronics for the electric kart. After spending over a week trying to diagnose and fix whatever caused our first ESC to not work we decided to purchase another unit (Link here: https://www.amazon.com/dp/B00DB0DNO6/). Once it was here I referred to the wiring diagram supplied by the seller for the hookup guide.

Boca Bearings Workshop Weekly Update 14

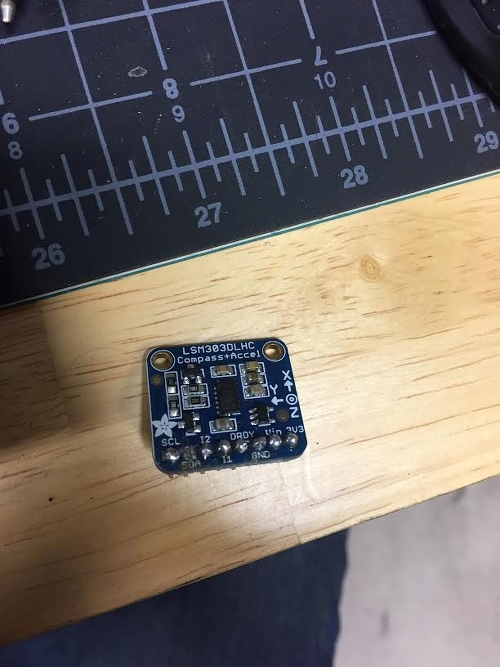

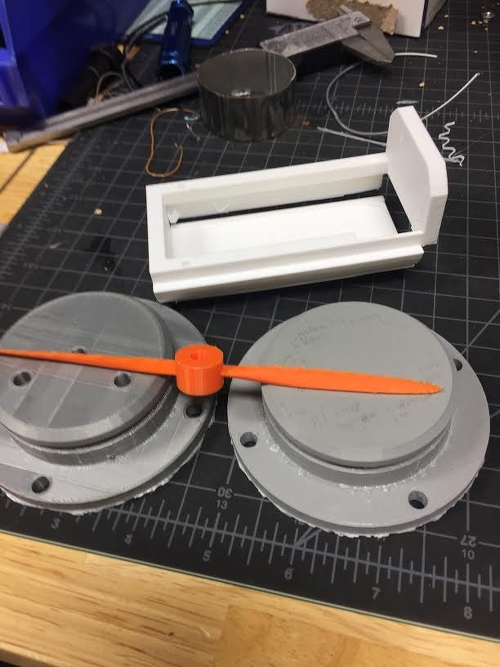

Some final adjustments were made to the hull of the sub. Using Solid works the hull was thickened for strength and and holes were added for the fin rods and mounting plate that hold the two halves of the shell together. The Arduino Uno, battery, and motor holder were 3D printed along with the propeller and end caps for the pressure vessel. The LSM303DLHC compass arrived and the pins were soldered on. Now code can be written and tested for finding the heading and speed.

Power Wheels Racer 2.0: Update 1

Over the past several months us here at The Workshop have been designing and fabricating the next generation of go-kart for our entry into this year’s Power Racing Series event at the Orlando Maker Faire. During last year’s event we found the old kart to simply be too big, too unwieldy, and too slow. Our aim with the new kart was to improve on these three aspects. First, a new frame was designed and welded together. WE salvaged certain parts of the old kart including the steering system and drive shaft but upgraded them with a full wheel in the front (instead of the old handle) and a 48V brushless motor (instead of the old 36V Brushed one). We hoped that the increase in voltage and switch to brushless would allow the kart performance to stay the same or increase while also increasing our run time.

Electric Skateboard Project Update 2

Quick update to the skateboard! In an effort to diagnose issues with another project I needed to salvage some known working parts from something and that turned into me pulling all the electronics out of the electric skateboard. After I was finished with the electronics, I decided to put it all back together but as soon as I looked at the old box full of hot glue, pieces of Velcro, and plastic shavings I decided to remake the box. I took another project box, same as before, and began by taking measurements of the box’s wall and also the three bullet connectors on the esc. I went into Fusion360 and made a bracket to hold the connectors on the inside and outside out the box. The inside bracket clamps down onto the bullet connectors locking the in place and preventing them from sliding around when I try to plug them in.

Subscribe to:

Posts (Atom)